Environment and coproducts

ENVIRONMENT AND RECYCLING OF PRODUCTION WASTE

In the 1980s, the cooperative’s members became aware of the importance of placing the environment at the heart of their development strategy. Then, they worked on the creation of solutions to accommodate environmental compliance and agricultural production.

With complementary activities incorporating our recognised expertise and cutting-edge technology, the environmental issues within the sector have become sources of added value for the cooperative.

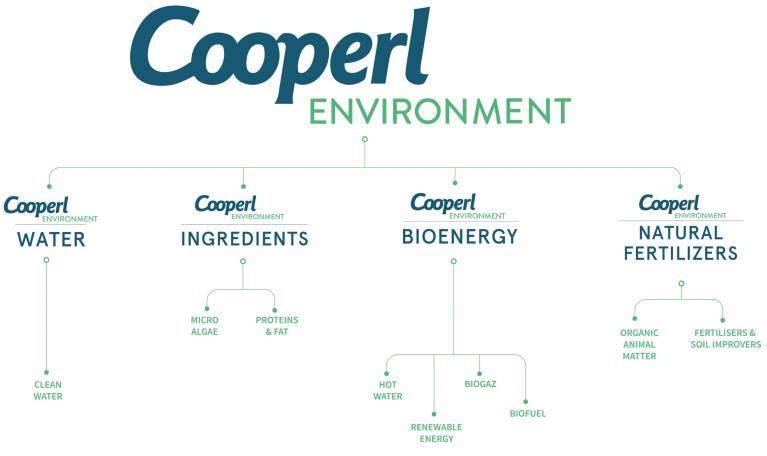

Our four areas of activities

Natural fertilizers

Fertilizers and amendments

Ingredients

Proteins and fats

Bioenergy

Biogas

Renewable energy

Biofuel

Waters

High environmental technologies

Cooperl Environnemnt currently consists of 9 complementary activities. We are 175 employees of which 16 are specialized in research & development to work within Cooperl Environnement. Our objective is to anchor in a sustainable way a circular economy approach: recycling of water, recovery of by-products, production of renewable energy and reduction of energy consumption.

In 30 years, 300 million euros have been invested to enable us to process 350 000 tonnes of co-products per year. A success of which we are proud.

Establishing a unique and responsible model based on the circular economy

In a context of the proliferation of environmental standards and the demands of wider society, we have established a value-creation strategy that continues to drive our activities: acceptance of environmental standards as a reality where (so-called) waste is a by-product offering potential added value.

Today, we are rightly proud of our unique, sustainable and responsible economic model. We are able to guarantee that our customers, consumers and citizens will receive high-quality products produced within a virtuous circle.

Innovating to create value

In 2019, we opened Europe’s largest methanizer free of agricultural spreading. Produced from organic material obtained from around one hundred farms fitted with the innovative TRAC technology, the biogas is fed into the GRDF network (a french network of gas distribution) and is equivalent to 75% of the domestic gas consumption of the city of Lamballe in France, head office of our cooperative. It means 60 million kWh per year or 10,000 homes powered by our biogas.

Unlike numerous other installations, it avoids all direct spreading of the digestate. This has been made possible by selecting a dual technology producing pure water at the end of the cycle, which is then re-used by the methanizer, and a natural fertiliser.

This project protects the environment, creates value and therefore improves farmers’ competitiveness.